Computational Net Zero Lab: Accelerated Discovery and Design of Materials, Systems, and Methods for Net Zero

Research Vision Statement: To develop sustainable solutions for clean energy storage and carbon dioxide capture for addressing the climate crisis through “people-first engineering.”

Research Interests: The goal of the Computational Net Zero Lab is to unearth, understand, and disseminate universal design guidelines (e.g., physical, chemical, materials-level, and system-level properties) to accelerate the discovery and design of materials for clean and sustainable energy (e.g., hydrogen, solar, battery) storage and carbon dioxide (CO2) capture to “catalyze America’s clean energy economy.” Following are the major areas of expertise of our lab:

- Understanding the origin of materials’ properties and behavior by using first principles methods (e.g., density functional theory [DFT], ab initio molecular dynamics [AIMD]) and molecular-mechanics-based approaches (e.g., molecular dynamics [MD], Monte Carlo [MC])

- Chemistry of Materials, 30, 2006-2017 (2018). DOI: 10.1021/acs.chemmater.7b05230

RSC Advances, 5, 35033-35041 (2015). DOI: 10.1039/C5RA04276C

Journal of Chemical Theory and Computation, 9, 2389-2397 (2013). DOI: 10.1021/ct301129x

Journal of Chemical Physics, 136, 154505 (2012). DOI: 10.1063/1.3702822

- Chemistry of Materials, 30, 2006-2017 (2018). DOI: 10.1021/acs.chemmater.7b05230

- Materials discovery and design (direct/inverse) using high-throughput computing and machine learning (ML)

- Nature Communications, 10, 1568 (2019). DOI: 10.1038/s41467-019-09365-w.

Energy & Environmental Science, 10, 2459-2471 (2017). DOI: 10.1039/C7EE02477K. Angewandte Chemie International Edition, 61, e202203575 (2022). DOI: 10.1002/anie.202203575 Patterns 2, 100291 (2021). DOI: 10.1016/j.patter.2021.100291

- Nature Communications, 10, 1568 (2019). DOI: 10.1038/s41467-019-09365-w.

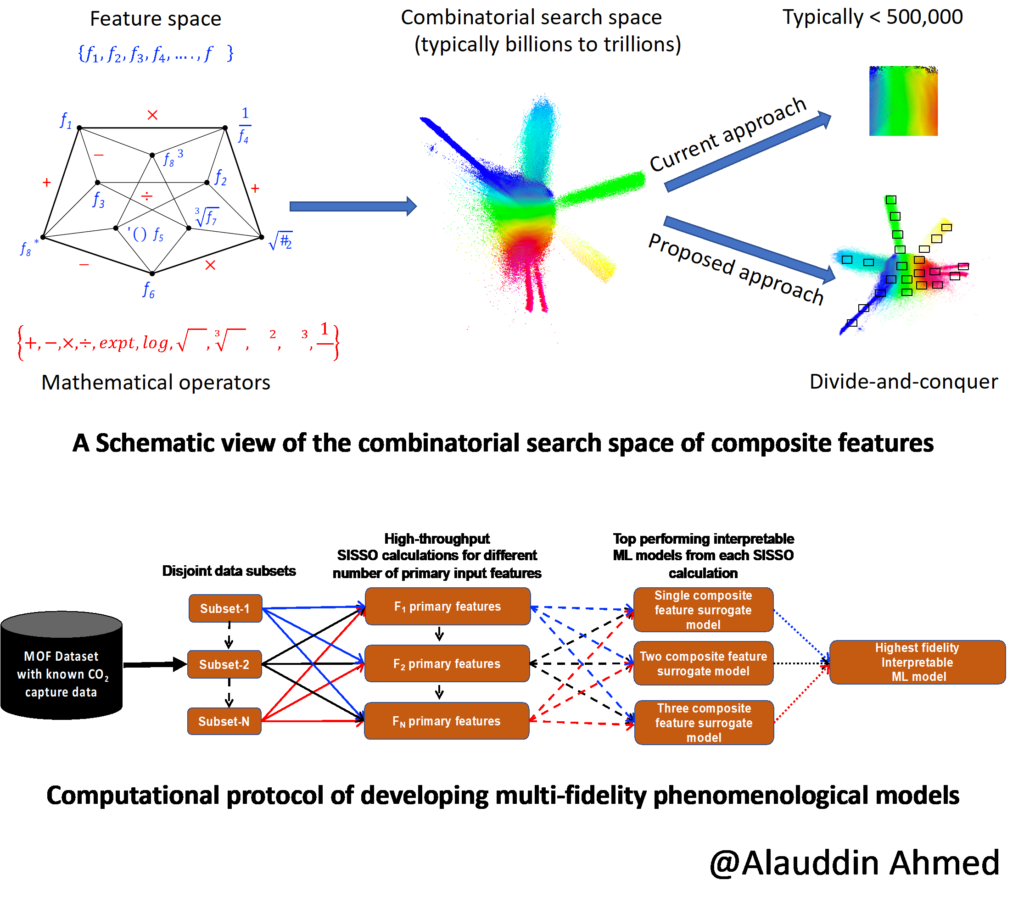

- Interpretable ML model development based on feature engineering and novel algorithms

- Patterns 2, 100291 (2021). DOI: 10.1016/j.patter.2021.100291

DOI: 10.26434/chemrxiv.1346987

- Patterns 2, 100291 (2021). DOI: 10.1016/j.patter.2021.100291

- Computational method development to understand fundamental mechanisms that govern materials behavior at different operating conditions and fast prediction of properties

- Journal of Chemical Theory and Computation, 9, 2389–2397 (2013)

RSC Advances, 5, 35033-35041 (2015)

Journal of Chemical Physics, 131, 174504 (2009)

AIChE Journal, 57, 250-258 (2011)

- Journal of Chemical Theory and Computation, 9, 2389–2397 (2013)

- System-level modeling by developing scale-bridging computational methods using the elements from finite-element methods (macro scale), ML (bridging method), and molecular simulations (micro scale)

- International Journal of Hydrogen Energy, 44, 15135-15145 (2019). DOI: 10.1016/j.ijhydene.2019.04.082

- Integrated computational approach, software development, and database creation

- Guide experimentalists to select materials for synthesis, interpret experimental observations, and understand materials behavior

- American Chemical Society, 144, 20939-20946 (2022). DOI: 10.1021/jacs.2c09818

Energy & Environmental Science, 11, 2784-2812 (2018). DOI: 10.1039/c8ee01085d.

Journal of Chemical Theory and Computation, 9, 2389-2397 (2013). DOI: 10.1021/ct301129x

- American Chemical Society, 144, 20939-20946 (2022). DOI: 10.1021/jacs.2c09818

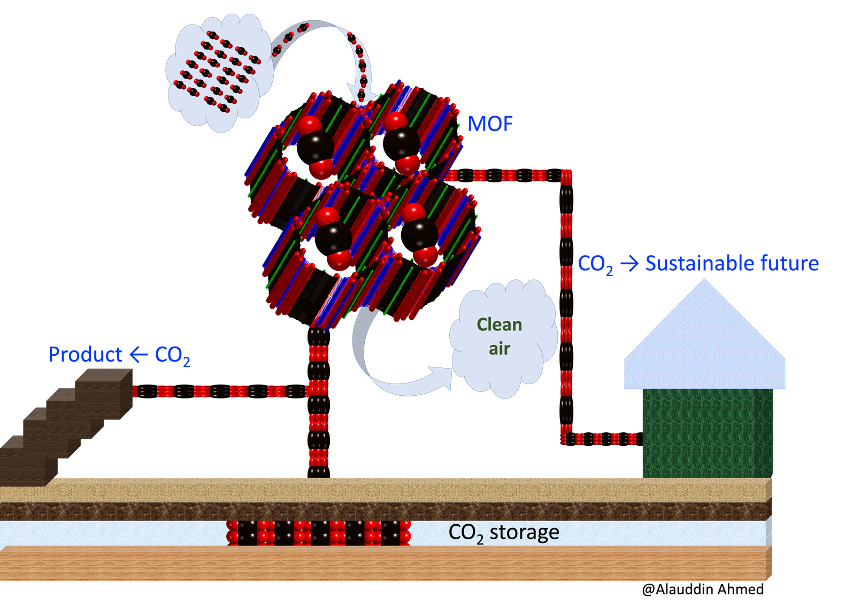

Research Thrust 1: Carbon Capture from direct air and industrial process

To protect the earth’s ecosystem from catastrophic damage, the Paris agreement sought to reach net-zero emissions by the middle of the 21st century. The U.S. is leading this effort and is poised to embark on achieving a net-zero economy by 2050. However, reaching this target will require the reduction of carbon dioxide (CO2) emission and the removal of CO2 directly from the atmosphere—direct air capture (DAC)—simultaneously. At present, amine scrubbing is the most widely used method for capturing CO2 from fossil fuel-fired power plants and DAC. Nevertheless, the high energy penalty (70-80% of the total energy consumption of CO2 capture process) during sorbent regeneration is one of the major cost driving factors, which impedes widespread adoption of this technology in coal/gas-fired power plants and DAC. Recently, materials-based CO2 capture has appeared as one of the most promising approaches. But identifying/designing the best-in-class materials for scalable carbon capture remains challenging. Our lab addresses these challenges by discovering/designing materials and developing advanced computational methods. At present, our lab focuses on the following projects:

- Understand atomistic/electronic-level mechanism that increases CO2 capture while decreasing materials regeneration energy

- Discover/design optimal materials with high CO2 capturability and low regeneration energy for developing economically viable technology

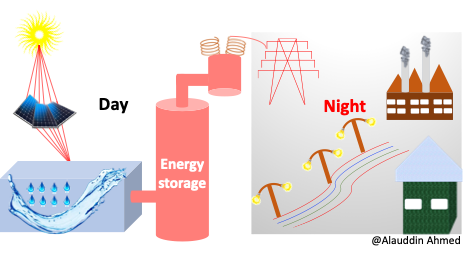

Research Thrust 2: Materials for Solar and Wind Energy Storage

The estimated $195 billion damage caused by the 2021 Texas power crisis highlights the importance of reliable and resilient electricity supply. However, the seamless supply of electricity, balancing demand and supply between peak and off-peak hours, depends on renewable sources and energy storage. The extraordinary recent efforts on developing cost-effective renewable energy systems have been driving the prices of solar and wind energy lower than ever before. However, the sun doesn’t always shine; the wind doesn’t always blow, so the supply of solar and wind energy is not continuous. Therefore, energy storage has become a critical component of a low-cost, reliable, carbon-free electric grid and renewable energy system. Currently, the so-called ‘solar salt’ (60:40 weight percent blend of sodium and potassium nitrate) is the state-of-the-art material for commercial solar energy storage worldwide. Albeit their high technological readiness (TRL 9), the existing molten salts are unlikely to meet the cost target set by the U.S. Department of Energy’s SunShot Initiative because of various reasons, including degradation at concentrating solar-thermal power (CSP) plant temperatures (i.e., >700 °C). To address this challenge, the following are the approaches of our lab:

- Understanding the atomistic level mechanism which increases thermal stability and volumetric energy density simultaneously

- ML-guided inverse design of molten slats with high thermal stability (i.e., stable > 700 °C) and high volumetric energy density

Research Thrust 3: Method Development to Accelerate the Discovery, Design,

and Scale-up of Materials

Materials are at the heart of current technological revolution that crosscuts energy and the environment. However, the gap between the increasing demand of low-cost, high-performance materials and the frequency of Edisonian trail-and-test approach of discovering such materials is widening day by day. Recently, ML/AI-based models have shown game-changing success in the discovery and design of materials at an unprecedented speed. However, widespread adoption of such data-driven methods is limited because of the following reasons:

- Often, ML models are trained and benchmarked against a relatively small dataset compared to the large design space of materials. Such ML models are likely to fail for materials with physical, chemical, and atomistic features completely different from those of the training set.

- While known interpretable/explainable ML methods (e.g., linear regression model) suffer from low predictive accuracies, highly predictive ML methods lack interpretability and act as black-box models. This trade-off limits our ability to design materials with desired properties/functionalities employing ML-based inverse design methods.

- The performance materials can vary at different length and time scales. Often, predictive models developed based on atomic-scale features cannot be used for the prediction of properties at the macroscopic scale. Therefore, a predicted high-performing candidate material could perform poorly at the system/device level. Such limitation is a major roadblock against scale-up of a new materials-based technology quickly.

To address these challenges, our lab focuses on the following projects:

- Develop ML-guided phenomenological models for screening millions to billions of materials with unprecedented speed

- Develop scale-bridging methods for predicting macro-scale performance based on atomistic-scale properties

- Integrate phenomenological models and scale-bridging methods within the inverse design framework of targeted materials design